The complexity of climate-controlled projects mandates that construction partners be well-versed in the entire development arc from site selection through estimation, procurement, and construction.

Selecting the right refrigerant for an industrial-scale cold storage facility will have significant impacts on how the structure is designed, built, and operated, as each phase will impact efficiency and profitability across the lifetime of the structure. The design, construction, and operation of cold storage facilities depend on several factors such as equipment selection, insulation, and maintenance. Like most modern technologies, constant innovation is rising to meet the challenges mandated by municipal environmental goals and industry-related economic realities. Natural refrigerants are increasingly being adopted as a response to environmental concerns and regulatory changes.

Refrigerant is a coolant used to extract heat from the air inside a given structure, be it a small home refrigerator or a large industrial cold storage warehouse. Coolant is constantly recirculated throughout the system, changing from vapor to liquid, and back again throughout this process. To understand how cold storage warehouses work, it is important to note that insulation, HVAC systems, and coolant circulation all play a critical role in maintaining the low temperatures required for proper storage.

In 2025, some of the most common coolants, hydrochlorofluorocarbons (HFCs, commonly known as Freon), are being phased out due to environmental concerns centered around the depletion of Earth’s life-protecting ozone layer. While some alternative blend freons remain in use, naturally occurring coolants like Ammonia and Carbon Dioxide (CO2) are now the mainstream, each with specific benefits for cold storage operators. Natural refrigerants such as CO2 and ammonia are now widely used in cold storage facilities due to their lower environmental impact.

As existing facilities in the cold storage ecosystem reach the end of their lifespans or are no longer able to operate efficiently, and new inventory is added to fill inventory gaps around the nation, the race is on to build the most efficient, cost-effective, and high-performance facilities as possible. Cold storage warehouses must maintain temperatures ranging from just above freezing to well below zero, depending on the products stored. As HFCs fade to memory, most of these new facilities and retrofits will use an Ammonia or Carbon Dioxide-based refrigeration system.

Designing an effective cold storage facility is a critical step in ensuring the long-term success and efficiency of any cold storage facility. The right design not only maximizes storage space and extends the shelf life of temperature-sensitive products but also plays a pivotal role in maintaining consistent temperatures and reducing energy costs across the entire cold storage warehouse.

A well-designed cold storage facility starts with robust insulation and vapor barriers to minimize heat transfer and prevent temperature fluctuations. High-quality insulation materials help maintain low temperatures and reduce the workload on the refrigeration system, resulting in greater energy efficiency and lower operational expenses. Properly sealed doors and loading docks are essential to prevent the intrusion of warm air and maintain a constant temperature, especially in high-traffic refrigerated warehouse storage environments.

Temperature control is at the heart of cold storage facility design. Advanced temperature regulation systems, including precise thermostats, air coolers, and remote condensing units, ensure that chilled air is evenly distributed throughout the storage facility. This is crucial for preserving the quality of perishable products, such as food, vegetables, and other sensitive goods, which require specific temperature and humidity levels to prevent spoilage and maintain freshness.

Humidity control is another key factor, as excessive moisture can lead to mold growth and product degradation, while too little humidity can cause dehydration and weight loss in stored goods. Modern cold storage cooling systems often incorporate humidity sensors and automated controls to maintain optimal conditions for a wide range of products.

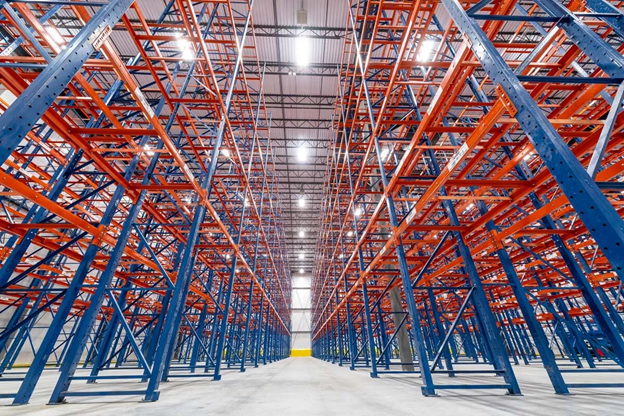

The layout and construction of a cold storage facility should also be tailored to the types of products being stored and the operational needs of the facility. For example, freezer rooms designed for frozen goods require different evaporating temperatures and airflow patterns compared to medium temperature cold rooms used for fresh produce. Adjustable racking systems and modular storage solutions can help maximize square footage and adapt to changing inventory requirements.

Finally, compliance with industry standards and local regulations is essential to ensure food safety, worker protection, and environmental responsibility. By partnering with experienced cold storage specialists, facility owners can create cost-effective, climate-controlled environments that support the demands of today’s supply chain and the evolving cold storage market.

According to the International Institute of All-Natural Refrigeration, Ammonia systems can be 10-20% less expensive to build. Ammonia is less expensive than HFCs to purchase, and thermodynamically gets the job done 3-10% more efficiently, yielding a significant cost savings to operators. Ammonia also has a distinctive smell, which makes leaks easier to detect before a full system shutdown occurs.

Ammonia systems have been in use for decades, with older facilities requiring a large amount of the refrigerant to operate reliably and efficiently. For Dot Foods in Oklahoma, FCL extended the life of an existing facility and expanded capacity by tying the air units of a new freezer penthouse into the existing ammonia refrigeration system.

Advancements in technology include new Ultra Low Charge Ammonia packaged refrigeration systems that require significantly less coolant and can now compete effectively in terms of operating cost and performance. The efficiency of a cold storage refrigeration system depends on the proper selection and integration of components such as the compressor, condensing unit, evaporator, expansion valve, and solenoid valve. By using less ammonia, often less than a pound of refrigerant per ton of refrigeration, production costs are reduced, and potential leaks have significantly less impact on worker safety and the environment.

For food service facilities, where frozen and refrigerated goods are extra sensitive to odors, we can use a two-step cooling process called Ammonia Glycol. Here, ammonia is used to cool glycol, an organic compound, which then enters the cooling chamber for circulation and heat extraction. The partitioned 710,000 square feet in cool/cold/frozen cooling space FCL built for a major retailer includes a 90,000 sq. ft. 0° freezer and an ammonia glycol 10,000 sq. ft. -10° freezer, where maintaining the correct evaporating temperature is essential for optimal performance and product preservation.

CO2 systems are growing in popularity, especially in coastal cities, where space is a concern or lower temperatures are needed, including those in the freezing and subzero range. These compact systems require smaller pipes and compressors, providing useful solutions in retrofits where space is limited, or in colocation facilities where controlled temperatures will vary in different sections. Remote condensing units and air coolers are often used in these systems to optimize space and efficiency in cold rooms.

While CO2 comes with a higher upfront cost and complexity to build, the benefits outweigh the challenges. CO2 is nonflammable, providing an added layer of worker safety. CO2 and other refrigerants function as gases that absorb and release heat during the refrigeration cycle, making them essential for cold storage cooling systems. On an environmental front, CO2 offers zero ODP (Ozone Depletion Potential) or GWP (Global Warming Potential), meeting advanced environmental standards that are phasing out HFCs.

The complexity of climate-controlled projects mandates that construction partners be well-versed in the entire development arc from site selection through estimation, procurement, and construction. For close to 40 years, FCL has worked in partnership with cold storage developers and owners/operators, delivering value and an exceptional experience at every step of the process. If you’re looking for a trusted and reliable partner, our cold storage specialists would be honored to talk with you.